Solar Atta Chakki

Solar Atta Chakki

A solar atta chakki is a flour mill that runs on electricity generated by the Sun. The six basic components of a flour mill powered by solar energy are:

1) Flour Mill.

2) Motor.

3) Solar panel.

4) Solar drive or VFD drive.

5) Solar panel stand.

6) Wiring.

The Flour Mill

The flour mill is the plant’s primary component. You should set up a mill with a minimum diameter of 20 inches so that you can produce 10 to 15 quintals of flour each day. You will get daily profits of between 2000 and 2500 rupees from it.

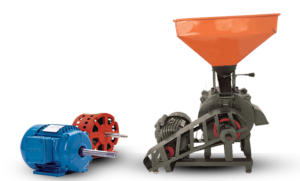

The Motor

The Solar Drive or VFD Drive

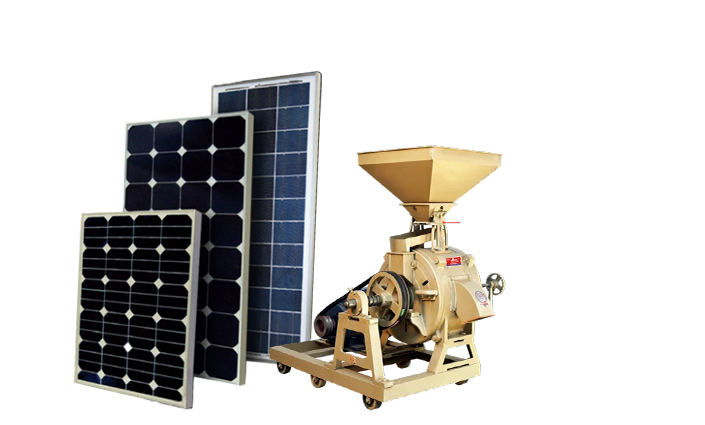

Solar Atta Chakki Panel

The solar atta chakki panel is the component of the solar flour mill that costs the most money. You generate electricity with the solar panel to power your grain mill. Solar panels come in a variety of designs, namely polycrystalline, monocrystalline, mono-perc, and bi-facial. When picking solar panel technology, one should keep in mind that the solar panel should provide you with the most power possible throughout the entire year. In order to avoid running into any difficulties, a mono perk solar panel is a better and more affordable solution that requires little maintenance and also generates electricity.

Bi-facial solar panels can also be put, by the way. Mono-facial solar panels only produce electricity from one side, whereas bi-facial solar panels produce electricity from both sides. However, we still recommend that you install just mono-facial mono-perk solar panels because they are simple to install and, on the other hand, won’t significantly boost your costs. Installing solar atta chakki panels has long-term benefits if we’re talking about bi-facial panels, but most individuals won’t even consider it because of the higher upfront cost.

Always install 2 to 3 kilowatt solar panels from the same horsepower motor, for example, if you have 10 kW solar panels on a 7.5 Hp motor and 12 kW panels on a 10 Hp motor. Apply this to ensure that your flour is thoroughly crushed regardless of how much or how little Sun there is.

Solar Panel Stand